LIMIT YOUR DOWNTIME AND IMPROVE EFFICIENCY WITH OUR INDUSTRIAL MAINTENANCE SERVICES

As Electrical And Mechanical Parts Age and Wear, They Always Seem To Fail At The Worst Time.

Direct replacements can often be unavailable as machines and equipment become older and obsolete and some manufacturers discontinue specific parts or go out of business – and parts that can be found may have altered specifications, different materials or redesigned connectors and interfaces. Making a new part or component work in your old machinery takes time, expense and may not even be possible.

Parts repair can be the faster, less expensive alternative to buying new equipment. A good manufacturing equipment service company, like Blue Willow , knows that manufacturers must keep their machines running with minimal downtime and strong cost savings, so quick turnaround and quality repairs are essential.

Increased Cost Savings. Improved Reliability

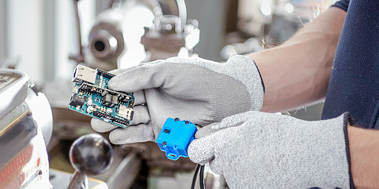

Our service facilities are best-in-class and ready to handle all your machinery and parts repair needs. Our highly skilled engineers have the experience and technical knowledge to perform every parts repair at the highest quality and to the designated specifications. From old I/O boards and PLCs to worn valves and servo motors, they are experts at it all.

Our parts repair services are geared toward your immediate needs – providing a fast and superior solution at a significant cost savings. In addition to our industrial machine repair services, we provide failure reports with suggestions for extending life and exclusive retrofit solutions for obsolete parts, if needed. We don’t just want to fix your part – we want to provide you the highest-level of quality to support the extended life of your equipment.

Our Expertise Make Us The Best Partner For You

Our Expertise Make Us The Best Partner For You

Our industrial machinery repair service spans a wide range of areas with the following focuses.

• Motor • Pump • Welding Equipment

• Electromechanical • Hydraulic Sstemsy • Electronics

Servo Motor Is Our Specialty

Our repair service for servo motors has gained special attention due to their in-built complexity and their almost ubiquitous presence within many of our customer’s internal manufacturing processes.

All servo motors are tested both statically and dynamically at our facility to insure proper operation. Encoders, resolvers, and tachometers are adjusted to correct the timing, waveform shape, offset position, voltage level, etc. Our rebuild process ensures that everything is reinstalled, properly sealed, repainted, and tested. All repairs are tested for quality assurance and must meet certain performance standards before leaving our facility. We maintain an extensive array of test equipment and offer complete run-testing and alignment of feedback devices to OEM specifications. Our software ensures that your feedback device is realigned correctly. We maintain the highest standard of quality control and take pride in our workmanship to guarantee that every motor is performing to its specifications.

We can repair your servo motors as we repair all top name brands. We can replace bearings, rewind the stator, test the encoder, repair the brake, and confirm the integrity of the permanent magnets on the rotor. Our years of experience gives us an advantage over the competition. We utilize the latest technology of test equipment in our electronics shop, Mitchell analyzers and Pico oscilloscopes.

Address:2880 Zanker Road, Suite 203, San Jose, CA 95134, USA.

Telephone Number: 408-850-8412

Email: info@bluewillowtech.com

Copyright © 2020 Blue Willow Tech All rights reserved.

Address:2880 Zanker Road, Suite 203, San Jose, CA 95134, USA. Telephone: 408-850-8412 mail: info@bluewillowtech.com

Copyright © 2020 Blue Willow Tech All rights reserved.